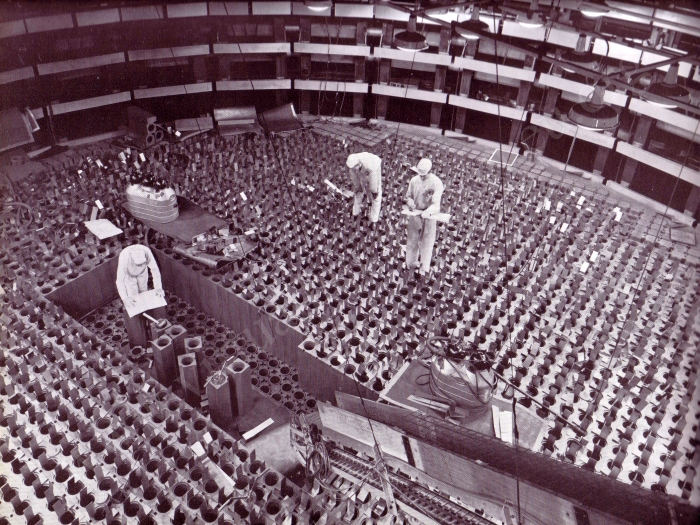

Safety was built in from the very foundations at Hunterston and the devices ranged from the massive concreete sheilding round the reactor vessels, 9ft thick at the sides and 10ft 6in thick across the top, to the sensitive instrumnets which automatically and constantly sample the gas from the 3288 fuel element channels in search of the slightest trace of radio-active fission products released by a failure of a fuel element can.

If one of the alloy cans enclosing the uranium should have developed the tiniest pinhole, invisible to the eye it would have been detected and immediately withdrawn from the reactor.

In the Hunterston design each individual fuel element was contained and seperately supported within a graphite sleeve. This provision gave amoung other benefits automatic protection against the build up of Wigner energy, a phenomenon which can cause sudden overheating within the reactor.

In the time from when the station started producting electricity till its decomissioning in 1988 there was not a single incident and was always number 1 in the worlds nuclear safety records.

If one of the alloy cans enclosing the uranium should have developed the tiniest pinhole, invisible to the eye it would have been detected and immediately withdrawn from the reactor.

In the Hunterston design each individual fuel element was contained and seperately supported within a graphite sleeve. This provision gave amoung other benefits automatic protection against the build up of Wigner energy, a phenomenon which can cause sudden overheating within the reactor.

In the time from when the station started producting electricity till its decomissioning in 1988 there was not a single incident and was always number 1 in the worlds nuclear safety records.